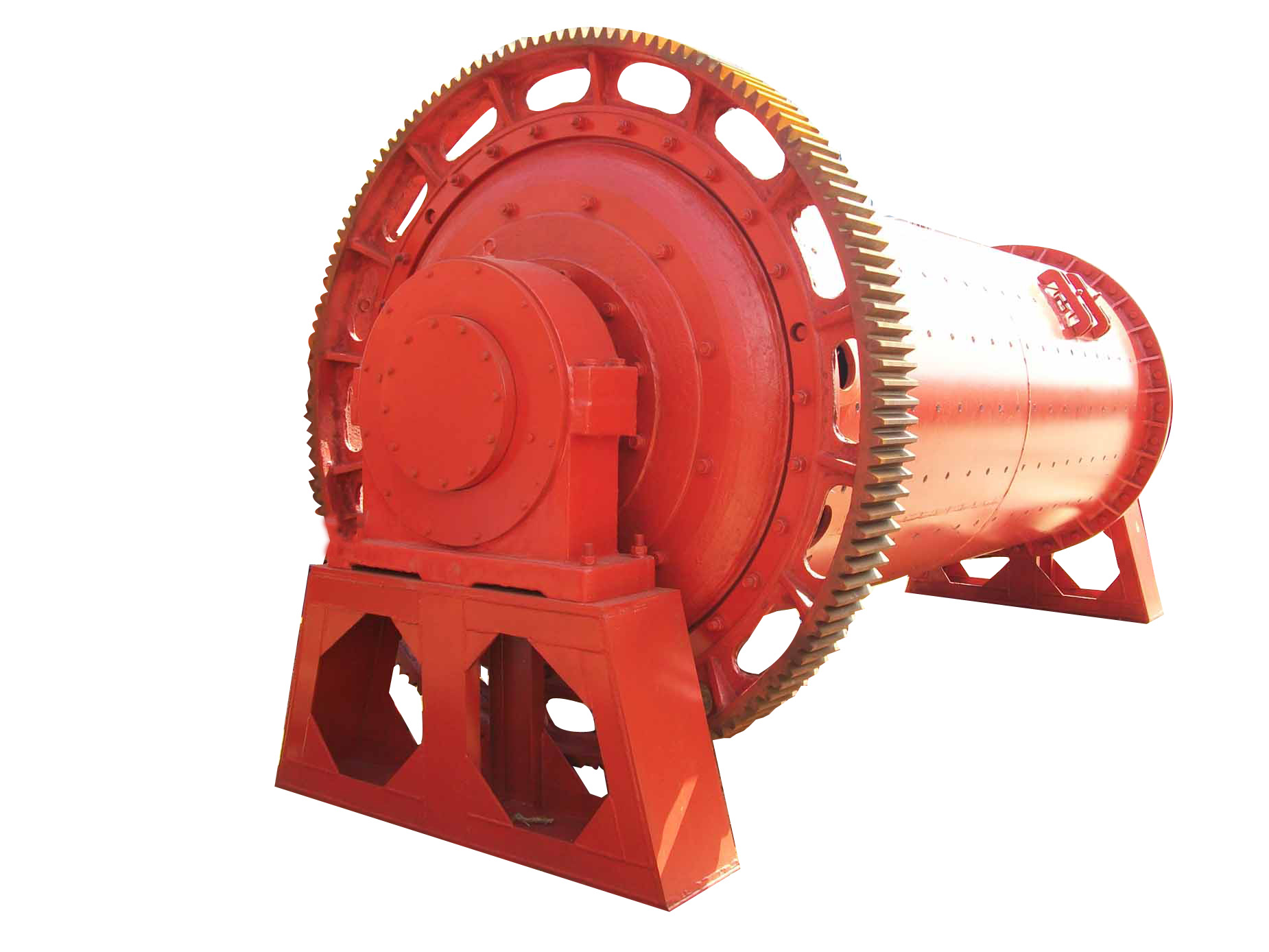

DescriptionsBall mill is vital grinding equipment after material is crushed. The Li Mai ball mill can be widely applied in cement, silicate product, new construction material, fireproofing material, chemical fertilizer, black and colored metal selection, glass, ceramic industries. All kinds of ores and other grinded material can be grinded by dry or wet way.

Working Principle

Energy-saving ball mill is horizontal cylindrical rotating device, outside edge gear transmission, two bins, grate ball mill. The material goes through feeding device to feeding hollow shaft screw and evenly into the mill first bin. This warehouse has step plate or corrugated plate, with different specification balls in it. Barrel rotational producing centrifugal force throws the ball to a certain height and then down, the material will be thumped and grinded. After the rough grinded in the first bin, the material will go to the second bin through the single diaphragms plate. Within the warehouse is flat plate and steel ball, the material will be further grinded. Powder content will come out through the discharge grating plate, finishing grinding operation.

Tructure Feature

Energy-saving ball mill is a new type ball mill which adopts the specific antifriction bearing as the barrel support structure and designed as the new idea. It solve the fowling problems: heavy duty rolling bearing life,regulating mental activitiesproblem, sealing problems under bad environment, barrel channeling dynamic after long time working.

Production Performance

Compared to traditional ball mill, ball mill with application of this technology motor power can reduce 18-25%, save oil 70%, save water 90%, comprehensive energy saving more than 20%.

Under normal circumstances, main bearing needn’t be changed within ten years, and it can save a lot of maintenance costs, and the working person and time. The main bearing use lubrication grease, which is convenient clean, exempting from the heavy metal pollution.

Technical Prameters

| specification |

Shell rotation speed(r/min) |

Ball load(t) |

Feeding size (mm) |

Discharging size(mm) |

capacity(t/h) |

Motor power(kw) |

weight(t) |

| Ф900×1800 |

38 |

1.5 |

≤20 |

0.075-0.89 |

0.65-2 |

18.5 |

3.6 |

| Ф900×3000 |

38 |

2.7 |

≤20 |

0.075-0.89 |

1.1-3.5 |

22 |

4.6 |

| Ф1200×2400 |

32 |

3.8 |

≤25 |

0.075-0.6 |

1.5-4.8 |

45 |

12.5 |

| Ф1200×3000 |

32 |

5 |

≤25 |

0.075-0.4 |

1.6-5 |

45 |

12.8 |

| Ф1200×4500 |

32 |

7 |

≤25 |

0.075-0.4 |

1.6-5.8 |

55 |

13.8 |

| Ф1500×3000 |

27 |

8 |

≤25 |

0.075-0.4 |

2-5 |

90 |

17 |

| Ф1500×4500 |

27 |

14 |

≤25 |

0.075-0.4 |

3-6 |

110 |

21 |

| Ф1500×5700 |

27 |

15 |

≤25 |

0.075-0.4 |

3.5-6 |

132 |

24.7 |

| Ф1830×3000 |

24 |

11 |

≤25 |

0.075-0.4 |

4-10 |

180 |

28 |

| Ф1830×6400 |

24 |

23 |

≤25 |

|

|

|

|