|

|

| Home >> PETROLEUM MACHINERY>> Drill Pipe >> Oil Drill Pipe |

|

|

|

|

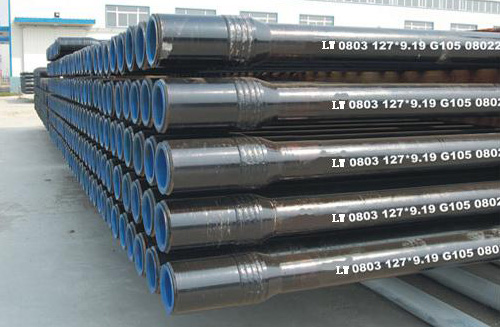

Oil Drill Pipe

We can supply all kinds of drill pipes that are consistent with API SPEC 5DP or SY.

Drill pipes can be made as customers’ requirements and be equipped with the same type of tool joints.

Advanced drill pipe production lines can transfer the welding parameters to the best position to ensure the quality of welding zone; the heat treatment process with the feature of internal and external cooling at the same time can make a more reliable and stable mechanical character. Application of automatic weight, length measurement and automatic spray records can ensure products’ traceability. Application of thickening and heating lines and 1250 tons of upsetting machine can ensure the thickening size meet the standard of API SPEC 5DR Using of CN furnace for whole pipe body heating and quenching, tempering machine’s advanced heat treatment process can ensure the pipe’s mechanical character. Tube hydraulic straightening machine ensures the straightness and coaxiality of pipe body.

Standard drill pipe specifications

|

Spec. |

OD of drill

pipe body |

Wall thk.

of drill pipe |

ODof

weld neck |

Tool joint |

RSC

chamfer diameter |

Approx.

qty. |

|

OD |

inter dia.

of male thread |

lenght of male

thread OD |

lenght of female

thread OD |

|

Spec. |

Spec. |

gra

- de |

|

RSC |

Ddp

mm |

t

mm |

Dteb

mm |

D

mm |

dp

mm |

Lpb

mm |

Lb

mm |

Df

mm |

Wdp

kg/m |

|

A.2 |

-12.5% |

MAX |

±0.8 |

+0.4

-0.8 |

±6.4 |

±6.4 |

±0.4 |

Cal. |

|

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

10 |

11 |

12 |

13 |

14 |

|

IU |

|

4 |

14.00 |

E |

IU |

NC40 |

101.6 |

8.38 |

106.4 |

133.4 |

71.4 |

177.80 |

254.00 |

127.40 |

22.42 |

|

4 |

14.00 |

S |

IU |

NC40 |

101.6 |

8.38 |

106.4 |

133.4 |

68.3 |

177.80 |

254.00 |

127.40 |

22.76 |

|

4 |

14.00 |

G |

IU |

NC40 |

101.6 |

8.38 |

106.4 |

139.7 |

61.9 |

177.80 |

254.00 |

127.40 |

23.61 |

|

4 |

14.00 |

D |

IU |

NC40 |

101.6 |

8.38 |

106.4 |

139.7 |

50.8 |

177.80 |

254.00 |

127.40 |

24.03 |

|

4-1/2 |

13.75 |

E |

IU |

NC46 |

114.3 |

6.88 |

119.1 |

152.4 |

85.7 |

177.80 |

254.00 |

145.26 |

22.50 |

|

2-3/8 |

6.65 |

E |

EU |

NC26 |

60.32 |

7.11 |

65.1 |

85.7 |

44.5 |

177.80 |

203.20 |

82.90 |

10.45 |

|

2-3/8 |

6.65 |

X,G |

EU |

NC26 |

60.32 |

7.11 |

65.1 |

85.7 |

44.5 |

177.80 |

203.20 |

82.90 |

10.58 |

|

2-7/2 |

10.40 |

E |

EU |

NC31 |

73.02 |

9.19 |

81.0 |

104.8 |

54.0 |

177.80 |

228.60 |

100.41 |

16.25 |

|

2-7/8 |

10.40 |

X,G |

EU |

NC31 |

73.02 |

9.19 |

81.0 |

104.8 |

50.8 |

177.80 |

228.60 |

100.41 |

16.25 |

|

2-7/8 |

10.40 |

S |

EU |

NC31 |

73.02 |

9.19 |

81.0 |

111.1 |

41.3 |

177.80 |

228.60 |

100.41 |

17.19 |

|

3-1/2 |

9.50 |

E |

EU |

NC38 |

88.90 |

6.45 |

98.4 |

120.7 |

68.3 |

203.20 |

266.70 |

116.28 |

15.77 |

|

3-1/2 |

13.30 |

E |

EU |

NC38 |

88.90 |

9.35 |

98.4 |

120.7 |

68.3 |

203.20 |

266.70 |

116.28 |

20.77 |

|

3-1/2 |

13.30 |

X |

EU |

NC38 |

88.90 |

9.35 |

98.4 |

120.7 |

65.1 |

203.20 |

266.70 |

116.28 |

21.76 |

|

3-1/2 |

13.30 |

G |

EU |

NC38 |

88.90 |

9.35 |

98.4 |

120.7 |

61.9 |

203.20 |

266.70 |

116.28 |

21.90 |

|

3-1/2 |

13.30 |

S |

EU |

NC38 |

88.90 |

9.35 |

98.4 |

120.7 |

54.0 |

203.20 |

266.70 |

116.28 |

22.22 |

|

3-1/2 |

13.30 |

E |

EU |

NC38 |

88.90 |

11.40 |

98.4 |

120.7 |

65.1 |

203.20 |

266.70 |

116.28 |

24.67 |

|

3-1/2 |

13.30 |

X |

EU |

NC38 |

88.90 |

11.40 |

98.4 |

120.7 |

61.9 |

203.20 |

266.70 |

116.28 |

25.07 |

|

3-1/2 |

13.30 |

G |

EU |

NC38 |

88.90 |

11.40 |

98.4 |

120.7 |

54.0 |

203.20 |

266.70 |

116.28 |

25.38 |

|

3-1/2 |

13.30 |

S |

EU |

NC40 |

88.90 |

11.40 |

98.4 |

139.7 |

57.2 |

203.20 |

266.70 |

127.40 |

26.19 |

|

EU |

|

4 |

14.00 |

E |

EU |

NC46 |

101.6 |

8.38 |

114.3 |

152.4 |

82.6 |

177.80 |

254.00 |

145.26 |

23.67 |

|

4 |

14.00 |

X,G |

EU |

NC46 |

101.6 |

8.38 |

114.3 |

152.4 |

82.6 |

177.80 |

254.00 |

145.26 |

24.12 |

|

4 |

14.00 |

S |

EU |

NC46 |

101.6 |

8.38 |

114.3 |

152.4 |

76.2 |

177.80 |

254.00 |

145.26 |

24.46 |

|

4-1/2 |

13.75 |

E |

EU |

NC50 |

114.3 |

6.88 |

127.0 |

168.3 |

95.3 |

177.80 |

254.00 |

153.99 |

23.65 |

|

4-1/2 |

16.60 |

E |

EU |

|

114.3 |

8.56 |

127.0 |

168.3 |

95.3 |

177.80 |

254.00 |

153.99 |

27.51 |

|

4-1/2 |

16.60 |

X,G |

EU |

|

114.3 |

8.56 |

127.0 |

168.3 |

95.3 |

177.80 |

254.00 |

153.99 |

28.07 |

|

4-1/2 |

16.60 |

S |

EU |

|

114.3 |

8.56 |

127.0 |

168.3 |

88.9 |

177.80 |

254.00 |

153.99 |

28.47 |

|

4-1/2 |

20.00 |

E |

EU |

|

114.3 |

10.92 |

127.0 |

168.3 |

92.1 |

177.80 |

254.00 |

153.99 |

32.93 |

|

4-1/2 |

20.00 |

X,G |

EU |

|

114.3 |

10.92 |

127.0 |

168.3 |

88.9 |

177.80 |

254.00 |

153.99 |

33.63 |

|

4-1/2 |

20.00 |

S |

EU |

|

114.3 |

10.92 |

127.0 |

168.3 |

76.2 |

177.80 |

254.00 |

153.99 |

34.34 |

|

4-1/2 |

16.60 |

E |

IEU |

NC46 |

114.3 |

8.56 |

119.1 |

168.3 |

82.6 |

177.80 |

254.00 |

145.26 |

27.36 |

|

4-1/2 |

16.60 |

X,G |

IEU |

NC46 |

114.3 |

8.56 |

119.1 |

158.8 |

76.2 |

177.80 |

254.00 |

145.26 |

27.73 |

|

4-1/2 |

16.60 |

S |

IEU |

NC46 |

114.3 |

8.56 |

119.1 |

158.8 |

69.9 |

177.80 |

254.00 |

145.26 |

28.04 |

|

4-1/2 |

20.00 |

E |

IEU |

NC46 |

114.3 |

10.92 |

119.1 |

158.8 |

76.2 |

177.80 |

|

145.26 |

32.94 |

|

4-1/2, |

20.00 |

X |

IEU |

NC46 |

114.3 |

10.92 |

119.1 |

158.8 |

69.9 |

177.80 |

254.00 |

145.26 |

33.69 |

|

4-1/2 |

20.00 |

G |

IEU |

NC46 |

114.3 |

10.92 |

119.1 |

158.8 |

63.5 |

177.80 |

254.00V |

145.26 |

33.97 |

|

4-1/2 |

20.00 |

S |

IEU |

NC46 |

114.3 |

10.92 |

119.1 |

158.8 |

57.2 |

177.80 |

254.00 |

145.26 |

34.23 |

|

IEU |

|

5 |

19.50 |

E |

IEU |

NC50 |

127.0 |

9.19 |

130.2 |

168.3 |

95.3 |

177.80 |

254.00 |

153.99 |

31.79 |

|

5 |

19.50 |

X |

IEU |

NC50 |

127.0 |

9.19 |

130.2 |

168.3 |

88.9 |

177.80 |

254.00 |

153.99 |

32.58 |

|

5 |

19.50 |

G |

IEU |

NC50 |

127.0 |

9.19 |

130.2 |

168.3 |

82.6 |

177.80 |

254.00 |

153.99 |

32.95 |

|

5 |

19.50 |

S |

IEU |

NC50 |

127.0 |

9.19 |

130.2 |

168.3 |

69.9 |

177.80 |

254.00 |

153.99 |

33.60 |

|

5 |

19.50 |

E |

IEU |

5(1/2)

FH |

127.0 |

9.19 |

130.2 |

177.8 |

95.3 |

203.20 |

254.00 |

170.66 |

33.22 |

|

5 |

19.50 |

X,G |

IEU |

5(1/2)

FH |

127.0 |

9.19 |

130.2 |

177.8 |

95.3 |

203.20 |

254.00 |

170.66 |

33.61 |

|

5 |

19.50 |

S |

IEU |

5(1/2)

FH |

127.00 |

9.19 |

130.2 |

184.2 |

88.9 |

203.20 |

254.00 |

170.66 |

34.89 |

|

5 |

25.60 |

E |

IEU |

NC50 |

127.0 |

12.70 |

130.2 |

168.3 |

88.9 |

177.80 |

254.00 |

153.99 |

40.73 |

|

5 |

25.60 |

X |

IEU |

NC50 |

127.0 |

12.70 |

130.2 |

138.6 |

76.2 |

177.80 |

254.00 |

153.99 |

41.80 |

|

5 |

25.60 |

G |

IEU |

NC50 |

127.0 |

12.70 |

130.2 |

168.3 |

69.9 |

177.80 |

254.00 |

153.99 |

42.11 |

|

5 |

25.60 |

E |

IEU |

5(1/2)

FH |

127.0 |

12.70 |

130.2 |

177.8 |

88.9 |

203.20 |

254.00 |

170.66 |

42.14 |

|

5 |

25.60 |

X |

IEU |

5(1/2)

FH |

127.0 |

12.70 |

130.2 |

177.8 |

88.9 |

203.20 |

254.00 |

170.66 |

42.51 |

|

5 |

25.60 |

G |

IEU |

5(1/2)

FH |

127.0 |

12.70 |

130.2 |

184.2 |

88.9 |

203.20 |

254.00 |

170.66 |

43.35 |

|

5 |

25.60 |

S |

IEU |

5(1/2)

FH |

127.0 |

12.70 |

130.2 |

84.2 |

82.6 |

203.20 |

254.00 |

170.66 |

43.75 |

Tensile Performance Parameters

|

Grade |

Yield strength |

Tensile strength |

|

Min. |

Max. |

Min. |

|

PSI |

Mpa |

PSI |

Mpa |

PSI |

Mpa |

|

E-75 |

75.000 |

517 |

105.000 |

724 |

100000 |

689 |

|

X-95 |

95.000 |

655 |

125.000 |

862 |

105000 |

724 |

|

G-105 |

105.000 |

724 |

135.000 |

931 |

115000 |

793 |

|

S-135 |

135.000 |

931 |

165.000 |

1138 |

145000 |

1000 |

|

| |

|

|

|